You now have a WSI vendor number. This means you can start to receive your first purchase orders from our Brands. This section guides you through what you need to do before you ship your first purchase order to us. Please read carefully and get in touch with us immediately if you are unsure of what you need to do.

- Purchase Order Management

- Quality Assurance Management

- Barcode Ticketing

- Carton & Pallet Marking

- Suffocation warning for vinyl & poly bag

- Product labelling

Purchase Order Management

You are responsible for managing your purchase orders and respecting agreed ship windows. WS Europe Purchase Order contacts will teach you how to accept Purchase Orders or request revisions and will support you with specific training materials ensuring smooth order placement.

This will allow you to better address any questions during your training session with WS Europe Purchase Order contacts. For pick up/delivery of the goods: For the invoicing process: If, due to a major delay, you are required to send a purchase order via air at your expense and decide to use your UPS account, please confirm the destination with us as ocean and UPS destinations might not be the same. As you are aware, the International Maritime Organization had implemented an amendment to the Safety of Life at Sea (SOLAS) convention to ensure safety of merchant ships. With this amendment , the VGM declaration (see the “Complete Shipper’s Guide” for reference) becomes effective July 1, 2016: any shipping container leaving from any port in the world must be accompanied by a shipping document, which should be signed either electronically or in hard copy by the shipper on the bill of lading listing the VGM (verified gross mass) of a container in order to be loaded onto a ship. The purpose of the VGM is to require the shippers of all containers to provide sufficiently in advance an accurate gross weight of the packed containers to the ocean carrier, so that terminal operators can prepare the vessel’s stowage plans prior to loading cargo on ships. Click Here Damco as the forwarder – for shipments not to USA: International Vendors: Payment Terms: Follow-up Questions: Savitransport as the forwarder – for shipments to USA: International Vendors: Payment Terms: Follow-up Questions:Accepting Purchase Orders

Purchase Orders are managed via GT Nexus Platform. Please read the GT Nexus User Guide![]() and e-learning video in anticipation of your 1st Purchase Order receipt.

and e-learning video in anticipation of your 1st Purchase Order receipt.

Invoicing and Shipping instructions

20 days before the ship date of your 1stPurchase Order WS Europe OM contact will guide you through the requirements regarding invoicing and shipping instructions.

![]() for Vendor Payment System Guide.

for Vendor Payment System Guide.![]() to access invoicing and packing list instructions

to access invoicing and packing list instructionsSpecial Shipments

Whilst most Purchase Orders are over 68kg and are shipped via ocean with our regional forwarders, any Purchase Orders that are less than 68kg must be shipped via UPS. All UPS shipments must be processed exclusively via the ShipExec website to ensure shipments are billed directly to WSI. WSI will not honour UPS shipments processed via UPS manual airway bill nor via the regular UPS website and non-compliance fees may apply. If you were not already given ShipExec website access during the development (pre-approval stage), ensure you are given access now by completing the ShipExec Request Form . Click here![]() to download the request form. Complete and email the form to

to download the request form. Complete and email the form to![]() . You will receive your ShipExec website User ID, Password and shipping instructions within 24-48 hrs of submission. Click here

. You will receive your ShipExec website User ID, Password and shipping instructions within 24-48 hrs of submission. Click here![]() on how to process your ShipExec shipments.

on how to process your ShipExec shipments.

Managing Ship Windows

Every time you receive a Purchase Order you are required to review production schedules and confirm viable delivery dates. When accepting your 1st Purchase Order ensure you evaluate additional timing required to complete product & lab testing, as well as registering with Avery Dennison for barcode label ordering. Important: Delays to agreed ship windows can lead to lost sales and financial losses to our Brands. Always strive to ship on time as in the case of a delay the Brand has the right to request an air shipment with vendor paying some or all of the costs. In the case of unforeseen issues which could cause a delay ensure you contact WS Europe Order Management Team immediately so that Brand inventory teams can be alerted as early on as possible.

SOLAS Requirements

![]() for further details Given these necessary changes, the WSI transportation team and our forwarders have collaborated regarding the changes and we have outlined the following:

for further details Given these necessary changes, the WSI transportation team and our forwarders have collaborated regarding the changes and we have outlined the following:

![]() for multiple containers or Click Here

for multiple containers or Click Here![]() single container) to provide the weight information to Damco, who will be responsible for filing the VGM with the carriers.

single container) to provide the weight information to Damco, who will be responsible for filing the VGM with the carriers.

![]() to access VGM declaration form. Please indicate whether a shipment is CY or CFS on this form, as it’s used for both service types.

to access VGM declaration form. Please indicate whether a shipment is CY or CFS on this form, as it’s used for both service types.

Quality Assurance Management

Items that are ordered for the first time (except Food) must be tested at a WSI-approved laboratory . Annual/Bi-annual retests are requested in case of reorders to ensure they meet functional standards and international legislation (e.g.: Cal Prop 65/FDA/CPSIA/EPA-TSCA* etc).You need to ensure that the product you are shipping to us passes our product quality, regulatory labelling, packaging standards and Purchase Order inspection before releasing the 1st Purchase Order to the forwarder. This is in conjunction with shipping purchase orders per the agreed ship windows.

*Formaldehyde Requierement for wood-based panels. ![]()

Important to know: at development stage, vendor is required to check the protocol under which their products will be tested (the protocol will be provided by WSGO EU QA Team), and advise if there are any performance requirements that cannot be met. In this case vendor will be required to fill in a Test Limitation Form (TLF) form that will be sent to QA and WSI brand for approval. Regulatory requirements must be met: no TLF is allowed.

Samples must be sent with the Test Request Forms (TRF) + Test Limitation Form (TLF) if present to allow the Lab proceeds with testing. Testing costs must be included in the first price confirmed to Merchants during the negotiation. Testing protocols depend on the product category/final use of the product (i.e: food contact or not, toy, electrics, etc..). All WSI Brands test globally except Rejuvenation and Mark & Graham that only test for USA markets. Retesting: existing products must be retested if the original report is over 2 years old. EU QA Team might evaluate the possibility to perform in-house drop test, instead of testing at the Lab. Tests are then repeated every 2 years, as long as that item is ordered, to ensure they meet our company standards. You need to ensure that the product you are shipping to us passes our product quality, regulatory labelling, packaging standards and Purchase Order inspection before releasing the 1st Purchase Order to the forwarder. This is in conjunction with shipping purchase orders per the agreed ship windows. No deviation are allowed from the approved packaging. If the pkg is not in accordance with the QA Packaging Waiver Form (issued by WSGO EU QA Team) or with the Lab Pkg testing report (Issued by the lab), vendors are liable for any claim from the DC. Packaging performance is monitored through the Scorecard and Retail in transmit damage rate. Corrective Actions can be taken when the packaging does not perform well.

B: .115 in. (2.92 mm) C: .148 in. (3.76 mm) E: .070 in. (1.78 mm) Please check the appropriate Spec. available under Chapters 6 of the WSI Foreign Vendor Manual which you can at: http://www.williams-sonomainc.com/vendor-compliance To access the website enter

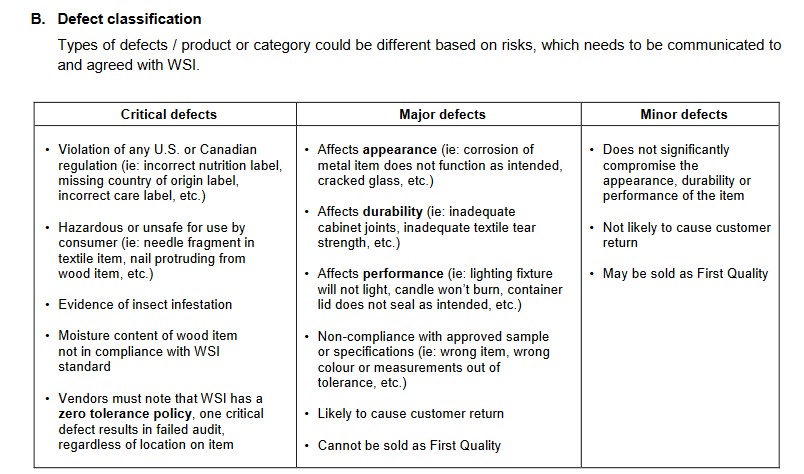

Williams Sonoma Inc. Acceptable Quality Level - standard Inspections by WS QA in no way release vendors of their responsibilities in shipping approved quality products in approved quality packaging marked and labeled per WSI requirements. Click here for Frequently Asked Questions for this topic. Product Testing

You will need to ship at your expense the required number of samples (quantity depends on the testing protocol for your product) to the designated testing lab. WS Europe QA will send you detailed testing instructions, including laboratory information and testing documents for you to prepare samples accordingly.

Packaging Testing

Items that are ordered for the first time must be tested at a WSI-approved laboratory . Packaging testing samples must be overpacked to the lab.

Test Results

WS Europe QA will send you official approval to proceed as soon as packaging test results become available. If testing fails WS Europe QA will instruct you on requirements to make proper corrective actions to pass a retest. A pass is required before you can ship your 1st Purchase Order.

Minimum performance requirements for master cartons:

Products

Board Type

Minimum Burst Test

Edge Crush Test

Minimum Caliper

Mail Order Conveyable and Retail Distribution Lot Quantity Inner Cartons

Single-wall (B,C,and E-Flute)

200 lb/in2 (1379 kPa)

32 lb/in (5.7 Kg/cm)

Soft Lines

Doublewall (B/C Flute)

150 lb/in2 (1034 kPa)

38 lb/in (6.8 kg/cm)

.255 in. (6.48 mm)

Hardlines

Doublewall (B/C Flute)

200 lb/in2 (1379 kPa)

42 lb/in (7.5 kg/cm)

.260 in. (6.60 mm)

Mirrors, Chandeliers and All Furniture Products

Doublewall (B/C Flute)

275 lb/in2 (1896 kPa)

48 lb/in (8.6 kg/cm

.260 in. (6.60 mm)

![]()

Inspections

WS Europe inspectors must be allowed access to your factory during production of an order and once production is completed, to verify quality and compliance of our orders before they ship. Our QA inspectors will schedule in-process inspections to ensure that the products meet quality and any pre-agreed tolerances (as established with WS Europe Merchant) and to check you are correctly labeling products and cartons.

Shipment Quantity

Sample size

Accept Up-to Level

Reject at or above

2 - 25

5

0

1

26 - 50

8

0

1

51 - 150

20

1

2

151 - 280

32

2

3

281 - 500

50

3

4

501 - 1200

80

5

6

120ì1 - 3200

125

7

8

3201 - 10000

200

10

11

10001 - 35000

315

14

15

35000 - 150000

500

21

22

150001 - 500000

500

21

22

500001 - +

500

21

22

Barcode Ticketing

All selling units for Retail and DTC (Direct to Customer) channels must be labeled with a WSI barcode sticker before shipping. Barcodes identify our products through our global supply chain. Avery Dennison & Fineline are our designated global ticket suppliers. You may order WSI barcodes online via the Avery/Fineline websites or print them in-house.

WS does not allow barcode purchasing/in-house printing prior to 30 days preceding the ship window due to the following reasons:

Regarding Retail Orders: in some cases, Retail prices may change and Avery system is automatically feed from WS systems, therefore shall reflect any Retail Price change. For any Retail price change, vendors are duly informed by WS Europe. Therefore, if for some reason, vendors are informed on any Retail price change and Avery system is still showing old Retail price, vendor is able to overwrite Retail price in the “Overwrite Retail Price” column. If tickets have already been ordered from Avery and Retail price change was made less than 30 days prior to ship window start date, vendors are not responsible for any re-ordering costs. However, if tickets have already been ordered from Avery earlier than 30 days prior to ship window start date, vendors will be required to re-order and re-ticketing product.

This is also valid for DTC (Mail) Order due to possible revisions on qty.

You have to download and compile the appropriate document: click here You can click here Important: You must indicate your WSI vendor number during registration. Completing your registration can take 2-3 business days + 7 business days to receive the orders stickers. Once you are registered you will be able to start ordering your WSI barcode tickets online. Please refer to the Vendor's Brief Guide to Barcode Labelling You can find here To simplify the ordering process for the bar code SKU labels through Avery Dennison’s online platform, WS has reduced the number of ticket item references available to order. The item references will no longer be differentiated by Destination Country or Channel. Bar code type to order as follows: WSM USA/ Mark & Graham orders = WSI-0912 (without retail price) WSR USA orders = WSI-0912 (with USD $ retail price, except for cookware and electrics that do not require the retail prices on bar codes) WSR Australia orders = WSI-0912 (with A$ retail price , except for cookware and electrics that do not require the retail prices on bar codes) WER UK orders = WSI-0912 (with £ retail price , except for cookware and electrics that do not require the retail prices on bar codes) WSR Mexico, Philippines, Alshaya, Korea = WSI-0912 (without retail price) WSR US orders containing Canada skus = WSI-0912 (with $ retail price* , except for cookware and electrics that do not require the retail prices on barcodes) *Canadian skus retail prices will not have the USD prefix *** retail prices on bar codes need to be the same as per the ones mentioned on the POS (or as per our office separate communications). If you see discrepancies on the Avery system, pls get in touch with our office. *** pls also check that Country of Origin is correct on bar codes. If you see discrepancies on the Avery system, pls get in touch with our office. To note: WSI-0912 refers to basic bar codes. If you need to order different type of bar codes, pls get in touch with our office Rejuvenation = owns a different procedure to order bar codes. Pls get in touch with Avery so as to proceed with the order. Bar codes do not have to show the retail price. The Avery-Dennison System will automatically link your orders to Removable or Permanent bar code type: With the expansion of our retail business into Australia (WS, PB, PBK, WE) and the United Kingdom (WE only), we are changing the SKU tickets that are to be put on product destined for these markets. We have worked with our partners at Avery Dennison to allow you to now order SKU tickets for these specific markets. The process for ordering is exactly the same as it is for a US SKU ticket. The only difference is that for Australia and the UK you will be selecting a different Avery Dennison item. Williams Sonoma Inc. has negotiated a contract with a new Service Provider for tickets, FINELINE which may be used as an alternative to AVERY DENNISON, Some further details on the service offered by Fineline: Bar code type to order as follows: WSM USA/ Mark & Graham orders = WSI-0912 (without retail price) WSR USA orders = WSI-0912 (with USD $ retail price, except for cookware and electrics that do not require the retail prices on bar codes) WSR Australia orders = WSI-0912 (with A$ retail price , except for cookware and electrics that do not require the retail prices on bar codes) WER UK orders = WSI-0912 (with £ retail price , except for cookware and electrics that do not require the retail prices on bar codes) WSR Mexico, Philippines, Alshaya, Korea = WSI-0912 (without retail price) WSR US orders containing Canada skus = WSI-0912 (with $ retail price* , except for cookware and electrics that do not require the retail prices on barcodes) *Canadian skus retail prices will not have the USD prefix *** retail prices on bar codes need to be the same as per the ones mentioned on the POS (or as per our office separate communications). If you see discrepancies on the FINELINE system, pls get in touch with our office. *** pls also check that Country of Origin is correct on bar codes. If you see discrepancies on the FINELINE system, pls get in touch with our office. To note: WSI-0912 refers to basic bar codes. If you need to order different type of bar codes, pls get in touch to our office Rejuvenation = owns a different procedure to order bar codes. Pls get in touch with FINELINE so as to proceed with the order. Bar codes do not have to show the retail price. For further evaluation, you may contact FINELINE Account Services directly, in order to obtain all the information required to select the bar code supplier of your choice. China shipments = China Representative: Daisy Wan Phone: 852 2156 9755 Email: dwan@finelinetech.com.hk Europe shipments = The Netherlands Representative: Maarten Minderhout Phone: +31 (0)8 8008 9600 Email: Pls be reminded that WSI requires that ticket adhesive be strong enough to remain on the product during transit and shelf-time at our stores & Distribution Centers. Regarding POS containing cookware and electrics items = bar codes DO NOT have to include retail price even if POS are for the Retail brand. Therefore bar codes for these divisions are always the same as the ones for DTC (without retail price). Fineline can offer a downloadable image for the ticket at a flat fee of $30, as well as the raw labels for printing (this is for the in-house printing option). Contact us for details and approvals. Rejuvenation barcode: see separate document under “In-House Printing” . Alshaya (ALS), Philippines (SSI), Mexico and Korea POs: Barcode with NO Retail price. Barcode to be applied onto the product. The exact barcode location will be confirmed by relevant contact from Merchandising Team. Australia (AUS) POs: Barcode with Australia $ currency. Barcode to be applied onto the product. The exact barcode location will be confirmed by relevant contact from Merchandising Team. UK POs: Barcode with GB Pounds currency. Barcode to be applied onto the product. The exact barcode location will be confirmed by relevant contact from Merchandising Team. Ordering via Avery Dennison

You need to register your company with Avery for billing and to be given on-line user access to the WCS website.

![]()

![]() to read the user guide.

to read the user guide.![]() for basic ordering guidelines and to chapter 6F of the WSI Foreign Vendor Compliance Manual for fuller instructions at http://www.williams-sonomainc.com/vendor-compliance access by entering

for basic ordering guidelines and to chapter 6F of the WSI Foreign Vendor Compliance Manual for fuller instructions at http://www.williams-sonomainc.com/vendor-compliance access by entering![]()

![]() the Avery Dennison Regional Customer Service Team contact information.

the Avery Dennison Regional Customer Service Team contact information.

![]() re: Australia and UK SKU Ticket Ordering Guide – guidelines for AUS/UK labels order on Avery’s website

re: Australia and UK SKU Ticket Ordering Guide – guidelines for AUS/UK labels order on Avery’s website

Click here![]() re: Frequently asked Questions

re: Frequently asked Questions

barcode type as mentioned above, which is without the retail price.

Ordering via FINELINE

In-house Printing

If you prefer to print WSI barcode tickets in-house you will need to match our barcode specifications, ensure that the barcode passes scan approval, ensure all tickets you print for our Purchase Orders always show correct information (eg: retail pricing).

However, tickets must be easy to remove from product without leaving ticket residue on product or ruining product surface (as most items sold in our stores are 'gifted' items).

Regarding Orders en route to Canada (from USA) = the required bar codes are almost the same as the ones for US destination. The only difference is in the retail price that will need to have format $ xx.xx – so it is without the USD prefix.

For WS USA (including Outlet), Australia and UK Click here for SKU Ticket Vendor In-House Print Guideline![]() .

.

For the Rejuvenation specs Click here ![]() Individually packed items should have bar code on exterior of the box.

Individually packed items should have bar code on exterior of the box.

For the Mark & Graham specs Click here ![]()

For the Mexico, Philippines and Alshaya destinations : Barcodes are the same as the ones used for WS US DTC (without the retail price).

Barcode Placement

USA/Canada POs:

► Retail POs: barcode with Retail price, as per PO’s copy. To be applied onto the product. The exact barcode location will be confirmed by relevant contact from Merchandising Team.

Note: Electrics, Cookware and Furniture: barcode without Retail price.

► DTC POs: Barcode with NO Retail price. To be applied onto the selling unit. Therefore:

Food Safe Logo

Food safe logo must be applied on food contact materials for all WSI brands (WS main included). Food grade logo sample image:

- Barcodes in-house printing: food safe logo to be added, click here

for detailed info.

for detailed info. - Barcodes purchased on Avery Dennison/Fineline systems: vendors must add the food safe logo, while ordering barcodes on AD and Fineline systems. See below for details.

Fineline Instructions:

The system has three dedicated ticket types added for ordering – these tickets with the food grade logo can be selected during the ordering process:

Avery Dennison Instructions:

Once you have entered your PO # or selected the item you want to place the order for, the Food Grade Logo field is the 2nd to the last field on the right

Once you select YES or NO, an image of the Food Grade Logo will appear.

Please note this logo will appear if you select YES or NO. This field will default to NO, so if you do not select YES or NO, you will be able to continue with your order. The Food Grade Logo will not print unless you select YES

Proceed with order placement like normal

Frequently Asked Questions

Click here for more information for this topic.Click here![]() for a brief guide to barcode labelling.

for a brief guide to barcode labelling.

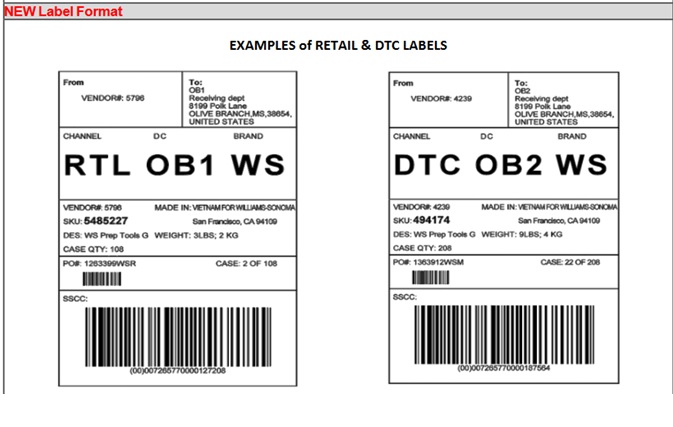

Carton & Pallet Marking

All packaging elements and pallets (if used) must be correctly labeled per our requirements in order to ensure our distribution requirements are met. Important: Wooden pallets shipping to the US must be fumigated according to U.S. law. Please check the appropriate chapters (8 & 9) of the WSI Foreign Vendor Manual which you can locate at:

http://www.williams-sonomainc.com/vendor-compliance

To access the website enter

![]()

Master Carton Labels:

- Label size: Approximately 4" x 3" (101 mm x 76 mm) to 4" x 6" (101 mm x 152 mm). Label sizes may be adjusted if the carton panel is too small for the label.

- Label location: Locate on the end panel, in the upper right hand corner of the carton with an identical label affixed to the adjacent side panel (with the carton in the normal shipping orientation).

This label printed on the MC is NOT allowed.

- SKU: WSI SKU number

- DES: WSI item description

- The best before date must indicate the following International codes. Only month and year. Example: JA 2017

|

JA – January |

JL – July |

||

|

FE – February |

AU – August |

||

|

MR – March |

SE - September |

||

|

AL – April |

OC – October |

||

|

MA - May |

NO – November |

||

|

JN – June |

DE – December |

- PO: Official WSI PO number

- QTY: Total selling units included in the master carton. This is not the ordered qty shown on the PO’s copy.

- MADE IN:

- the name of the Brand might be Williams Sonoma, Pottery Barn, Pottery Barn Kids, West Elm, Mark&Graham, etc..

- Address on master carton label will be based on PO destination.

Example: Made in Italy for Williams Sonoma, San Francisco CA 94109

USA&Canada

for REJUVENATION

Made in … for (Brand*), Portland, OR 97210

for all other brands

Made in … for (Brand*), San Francisco CA 94109

Australia

(all brands)

Made in … for (Brand*), Horsley Park, 2175

UK

(all brands)

Made in … for (Brand*), Northants NN18 8EY

Philippines

(all brands)

Made in … for (Brand*), Singapore 539775

Korea (Livart)

(all brands)

Made in … for (Brand*), Singapore 539775

Mexico (Liverpool)

(all brands)

Made in … for (Brand*), Singapore 539775

Alshaya

(all brands)

Made in … for (Brand*), Singapore 539775

India (Reliance)

(all brands)

Made in … for (Brand*), Singapore 539775

*The name of the Brand might be Williams Sonoma, Pottery Barn, Pottery Barn Kids, West Elm, Mark&Graham, etc..

- WEIGHT: Approximate Gross weight is sufficient

NOTE: All vendors must continue to use the above Label Format until they are contacted by their Local WSGO Office (main contact Dogu Akincilar DAKINCILAR@WSGC.com ) to make the change to the NEW Label Format.

Important for food products: new label format does not have the best before line. Vendors must add on the master carton a separate sticker with the best before date.

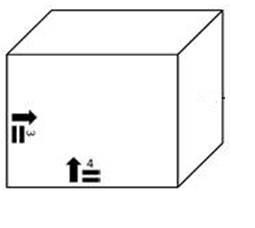

Handling Symbols:

- Symbol of glass is requested for fragile product only.

- The arrow is requested for all product categories.

- Stacking symbol is required for all master cartons which are prone to stacking (compression) damage.

Vendor should determine the maximum allowable cartons on a uniformed straight column stack to a maximum height of 110 inches (279 cm).

Number above rectangles indicates the number of allowable cartons to be stacked. The number “1” in this position indicates that no stacking is allowed.

2 identical labels to be positioned on the two smaller vertical panels of the carton. They can be on adhesive label or printed directly to the MC.

- Center all applicable handling symbols on smaller carton panels, side to side (if panel size permits) or vertically (if panel is narrow):

- Large: 4 in x 6 in (10.2 cm x 15.25 cm) for cartons with major panel dimensions of 42 in x 42 (106 cm x 106 cm) or larger

- Medium: 3 in x 4 in (7.6 cm x 10.2 cm) for cartons with major panel dimensions between 25 in and 42 in (63.5 cm and 106 cm) high and wide

- Small: 2 in x 3 in (5.1 cm x 7.6 cm) for cartons with major panel dimensions between 10 in and 25 in (25 cm and 63.5 cm) high and wide

- Symbol Spacing: Each handling symbol must be 1 in (2.54 cm) apart for large size and 0.5 in (1.27 cm) apart for medium and small size symbols

- In order to optimize container loading, it is an option to is use the double arrows on cartons. The vendor is responsible to decide if the product is safe when stacked in the two designated orientations.

When the double arrow is present, it is necessary to add the stacking symbol for that orientation as well.

While determining the maximum allowable cartons, pay attention not to exceed 110 inches (279 cm).

Additional Master Carton Labeling:

- Take To Receiving Department Labels (Pink): Required for Pos that are sent via UPS/CVS to US. Apply to opposite vertical panels of each master carton.

- Heat Sensitive Product: Green labels. Specially required for soaps and candles. Apply to opposite vertical panels of each

- Cold Room: Cold Storage Labels (Blue) is required for temperature-sensitive items. Apply to opposite vertical panels of each master carton. It can be on adhesive label or printed directly to the master carton.

NOTE: cold room label does not mean that product is stored in a refrigerated area. Item is placed in a temperature controlled room.

It is vendor responsibility to indicate if the product needs or not the “cold room” label.

Inner Carton Labels:

When the master carton (MC) quantity does not equal the distribution lot (DL) quantity, the inner cartons must have two inner carton labels.

Label location and Printed information: Same as master carton labels, except the Weight: NOT needed

Label size: Approximately 1" x 2.25" (25 mm x 57 mm) to 4" x 2" (102 mm x 50 mm). Label sizes may be adjusted if the carton panel is too small for the label.

Inner carton label NOT needed when the barcode sticker is visible outside its package (e.g. product in a transparent poly bag) or when there is the 2nd barcode outside the individual protection.

Palletized Marking Requirements:

Type of pallet accepted by WS Inc.: With the aim to reduce the non-recyclable pkg materials as much as possible (eco sustainability policy), WSI is transitioning to paper pallets in all SEA shipments. The feet can be constructed of vertical corrugated sheets that are laminated together or they can made of honeycomb, both are acceptable. Please get in touch with your relevant EU QA person for detailed info.

All pallet loads must be labeled as per following specifications. See label example below.

Label size: Approximately 8.5" x 10" (203 mm x 269 mm).

Label Location: Locate centered on a vertical side of the pallet load. An identical label must be place on the opposite vertical side. See diagram below.

Printed information:

* QTY is the Total selling units included in the pallet load. Note that a selling unit may be a set (i.e. set of 4 pieces)

“MIXED LOAD” LABEL:

- Ship only one SKU/ one PO per pallet is preferable.

- If more than one SKU or PO*, must be loaded on the same pallet, ensure such pallets are marked “Mixed Pallet”.

- The label must be placed on all 4 pallet sides.

- When we have a “mixed pallet” label, it is not necessary to also add the pallet label. The “mixed pallet” label is sufficient.

*make sure the destination address of POs is exactly the same.

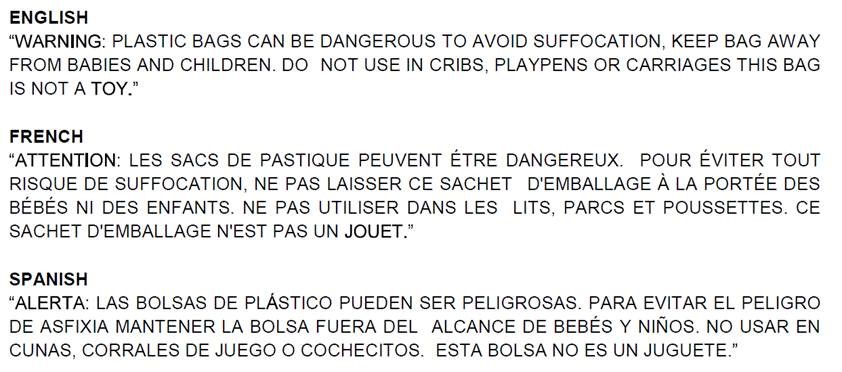

Suffocation warning for vinyl & poly bag

Vinyl bag or Poly bag:

The plastic bag must be well sealed. The Suffocation Warning must be legibly printed or permanently labeled on the plastic bag.

The warning is needed when the minor dimension of the bag is 3.94 inches (100 mm) or more.

Bag dimensions shall be measured while in the form of a bag not cut open into a single thickness sheet.

The minor dimension of the bag is the smallest of either the bag length or bag width.

The warning statement must be printed in English, French and Spanish.

WARNING STATEMENT FONT SIZE

![]()

THICKNESS:

- Plastic bags, used for children's items (Pottery Barn Kids, Pottery Barn Teen, and any other products specifically marketed for children) must be a minimum of 2 mils (0.05 mm) thick.

Exception: when the minor dimension of the bag is 3.94 inches (100 mm) or less, there must be a minimum of 1.25 mils (0.03 mm) thick. - Plastic bags used for adult items must be a minimum of 1.25 mils (0.03 mm) thick.

Click here for Frequently Asked Questions